Star Pipe foundry India Pvt Ltd.

Where Engineering Starts with Innovation!!!!

- At Star Pipe Foundry India Pvt Ltd, we pride ourselves on being more than just a foundry. We are a fusion of different processes, traditional craftsmanship and cutting-edge innovation, all under one roof. With a diverse range of processes and a team of skilled technicians, we bring your visions to life with unparalleled precision and quality.

- Explore our world of metallurgical mastery, where every pour, mould, and finish is executed with passion and expertise. Whether you're in need of intricate castings, specialized alloys, or custom solutions, from 125gms to 400Kg we stand ready to exceed your expectations.

- An amalgamation of Most Morden processes including Highly automated Disa, Semi Automatic Arpa 1300, Lost Foam, shell moulding, finishing capabilities of all sizes and coating. Not ending here maintaining and exporting 300 Containers per month.

- Discover the artistry of Star Pipe Foundry India Pvt ltd, where excellence is forged through diversity

Over 3 years of Operation

0

+

Team of Professionals

0

+

Acre Plant

0

+

M.Ton Export

0

+

Workers

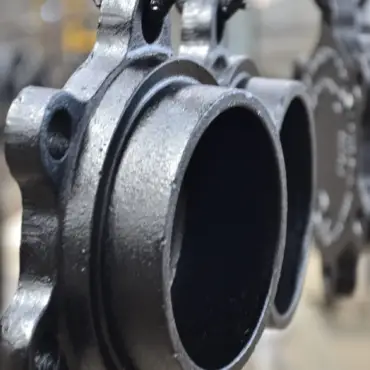

Our Products

Why Select Us

This foundry offers an end-to-end solution for customers. From initial design to final machining and special coating, it covers the entire casting process. This eliminates the need for customers to coordinate with multiple suppliers, streamlining the production process.

State-of-the-Art Designing

The advanced design capabilities signify a focus on precision and innovation. The foundry can assist in optimizing designs for manufacturability, potentially leading to cost savings and better-performing components.

Optimized Casting Techniques

The presence of Shell Molding, Lost Foam Process, High-Pressure Casting, and Semi-Automatic Processes means the foundry can choose the most suitable method for each specific application. This leads to higher-quality castings, reduced costs, and improved efficiency.

Machining Expertise

In-house machining capabilities offer a seamless transition from casting to finished product. This ensures tight tolerances, precise dimensions, and high-quality surface finishes, reducing the need for additional processing steps.

Specialized Coating Process

The ability to apply specialized coatings enhances the performance and durability of cast components. This is particularly crucial for applications in demanding environments or industries.

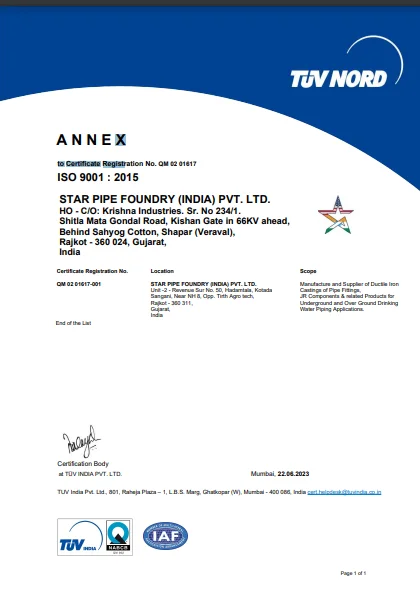

Quality Assurance

A foundry with such advanced capabilities is likely to have stringent quality control measures in place. This can lead to higher confidence in the reliability and consistency of the castings produced.

Versatility across Industries

The foundry's ability to cater to various industries and applications, such as automotive, aerospace, marine, and more, means it can adapt to a wide range of customer needs.

Innovation and Technology Adoption

The presence of state-of-the-art processes indicates a commitment to staying at the forefront of industry advancements. This means customers can benefit from the latest technologies and techniques.

Supply Chain Management

Assisting in managing the procurement, inventory, and logistics aspects to ensure a smooth flow of materials and components.

Industries we serve

Our Market Segment